From Industrial Overmolding to 3D Tool-Changers: How Multi-Material 3D Printing Is Redefining Product Prototyping

In the plastics industry, overmolding and two-shot molding have long been key processes for combining multiple materials within a single part: rigidity and flexibility, integrated sealing areas, color contrasts, or textured surfaces.

Until recently, these technologies were confined to industrial injection molding, along with its tooling constraints.

Today, multi-material 3D printing is breaking down that barrier. Combined advances in mechanics, electronics, and software now make it possible, even at the prototyping stage, to achieve what once required complex and costly molds.

Being able to integrate rigid structures, flexible zones, functional seals, or soluble supports into a single prototype fundamentally changes how design offices conceive, test, and validate products. Multi-material 3D printing is no longer an experimental luxury; it has become a strategic tool for product development.

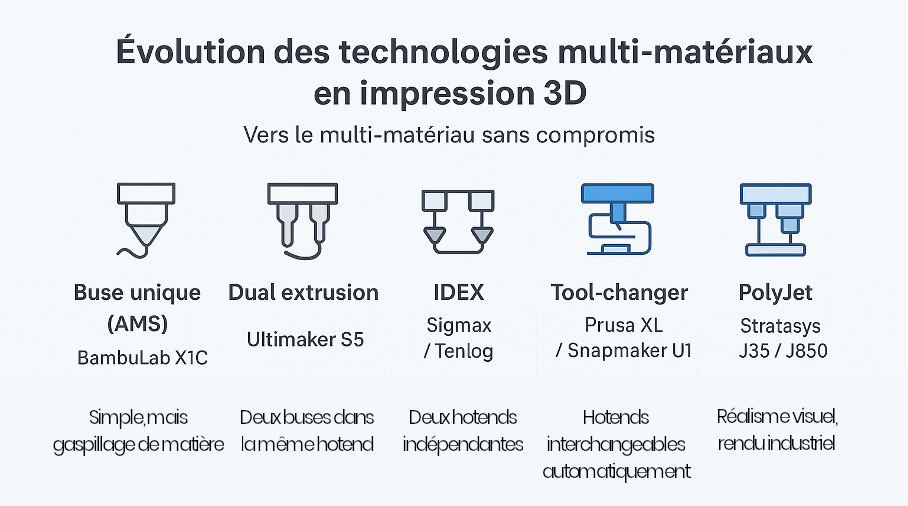

The simplest approach: one nozzle, multiple filaments

Systems like the Bambu Lab X1 Carbon and its AMS module have popularized “accessible” multi-material printing. The principle is simple: a single extrusion nozzle combined with multiple filament spools managed by an automatic loading system.

Color or material changes are handled through a purge sequence, designed to clear the nozzle before feeding in the new filament.

✅ Advantage: simplicity, controlled cost, and excellent software integration.

❌ Drawback: each material change requires significant purging, resulting in non-negligible waste. Some materials are incompatible due to temperature constraints—particularly flexible materials like TPU, which are generally not supported by AMS-type systems.

This approach is effective for multi-color prints or occasional bi-material use, but it remains poorly suited to intensive industrial applications, where process repeatability and cleanliness take precedence over convenience.

Dual Extrusion: The Transition to functional prototyping

Dual-nozzle systems, such as those offered by Ultimaker or Raise3D, have paved the way for truly multi-material 3D printing.

Each nozzle has its own dedicated extruder and can be configured independently, making it possible, for example, to use a rigid PLA filament for the structure and a soluble PVA material for the supports.

🔧 Key advantages: Reduced purging, better material compatibility, independent nozzle settings.

⚙️ Contraints: More complex calibration, risk of oozing if nozzles remain too close, software workflows that can be demanding.

This technology long represented the best compromise between flexibility and reliability. However, it reaches its limits as soon as you try to combine multiple materials with very different thermal behaviors (heat creep), or when full production automation is required.

IDEX: two independent toolheads, a major qualitative leap

IDEX (Independent Dual Extrusion) printers, such as the Sigmax or Tenlog models, go even further.

They feature two fully independent toolheads, each moving on its own X axis. The result: while one toolhead is printing, the other remains parked—eliminating cross-contamination and enabling the parallel printing of two identical parts.

🎯 Advantages: reduced idle time, improved quality during material transitions, and “mirror” or “duplication” modes that are highly useful for rapid production.

🧩 Limitations: increased mechanical complexity, higher cost, and more time-consuming multi-toolhead calibration.

For advanced prototyping, this approach is already a powerful lever: it makes it possible to produce parts that combine rigidity, flexibility, and even conductivity (using specialized filaments) without relying on post-assembly processes.

Tool-Changers: The Emerging new standard

The new generation of semi-professional 3D printers introduces a far more ambitious concept: automatic tool changing.

Each print head — or even each tool — becomes an autonomous module that the machine can pick up and dock as needed.

State of the Art in 2025

- Prusa XL: up to five tools, already widely adopted for functional prototyping.

- Snapmaker U1: now commercially available, positioning itself as a highly capable solution with four independent print heads, robust kinematics, and aggressive pricing for the semi-industrial segment.

- Prusa – INDX system on the CORE One: a new tool-changing approach focused on reliability, precision, and industrial integration, clearly designed for intensive use.

- Bambu Lab – Vortek system on the H2C: a notable entry into tool-changing architectures, aiming to combine Bambu Lab’s software expertise with a purge-free multi-head system.

🚀 Key advantages: near-elimination of purging, compatibility between very different materials, increased speed, and consistent quality.

💡 Challenges: mechanical complexity, multi-tool calibration management, and higher upfront cost.

But the industrial value is clear: no more material waste, no more downtime for nozzle changes, and no more manual adjustments. Tool changers pave the way for smoother automation in prototyping and agile production, where a single machine can seamlessly switch between materials, textures, and functionalities without human intervention.

PolyJet: the benchmark for high-fidelity multi-material printing

PolyJet technology, developed by Stratasys, is based on photopolymer jetting: multiple liquid resins are deposited and cured simultaneously using UV light.

Each droplet can have a different color, hardness, or level of transparency, making it possible to replicate the complexity of industrial overmolding—without a mold.

🎨 Advantages: exceptional resolution, highly realistic visual and tactile rendering, the ability to combine flexible and rigid materials, as well as translucent and opaque ones.

⚠️ Limitations: high cost of machines and resins, specific maintenance requirements, and parts with lower mechanical strength.

Models such as the Stratasys J35 Pro or the J850 Prime make it possible to simulate multi-material assemblies in a single print, with a level of realism that is difficult to match with filament-based processes.

A powerful efficiency lever for product development

The integration of these new multi-material technologies is transforming the way design offices manage their iteration cycles:

- Shorter lead times: fewer machine stoppages and greater autonomy.

- Improved validation: a single prototype can now combine the functions of multiple parts.

- Material savings: elimination of purge cycles and optimized support structures.

- Better communication: more realistic visual and functional prototypes, making collaboration between design, engineering, and marketing teams easier.

In the long run, these innovations point toward a convergence between additive manufacturing and flexible micro-fabrication, where the boundary between prototype and end-use part gradually disappears.

Conclusion

Multi-material 3D printing is bringing the world of prototyping closer to industrial production.

What plastics manufacturing has achieved for decades through overmolding or bi-injection, modern 3D printing systems now make possible—without tooling or long lead times.

From single-nozzle systems like Bambu Lab to tool-changer architectures such as the Prusa XL or the upcoming Snapmaker U1, the prototyping chain is becoming cleaner, faster, and more agile.

For design offices, this represents an opportunity to shorten design cycles, test innovative materials, and deliver high-value prototypes more quickly—all with a reasonable machine investment.

The future of product development is now being written in multi-materials, a transition already underway in the most agile workshops.