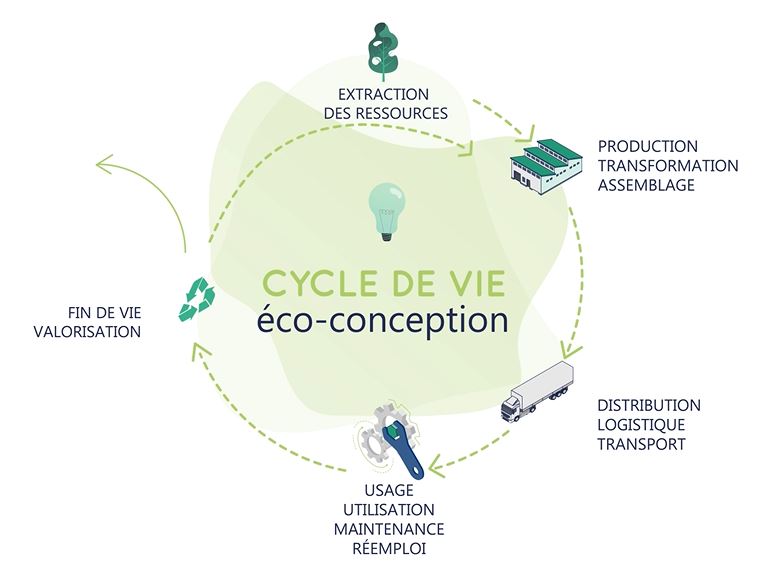

Eco-design is no longer just a marketing argument: it has become an essential practice for designing durable, reliable, and responsible products. Every design decision and every technical choice directly influences a product’s environmental footprint and can have a significant impact on its lifespan, reparability, and resource consumption.

In the development of new products, several levers make it possible to integrate sustainability without compromising performance or user experience.

In the development of new products, several means make it possible to integrate sustainability without compromising performance or user experience.

Reducing PCB size and complexity

One of the main pillars of eco-design is the optimization of electronic boards. Reducing the size and complexity of PCBs involves rationalizing components, simplifying routing, and eliminating redundancies.

The benefits are numerous: reduced material consumption, lower energy requirements during manufacturing, simplified maintenance, and improved reliability. At this stage, every electronic function is questioned: is it truly necessary? Can it be replaced by a mechanical or software-based solution?

Favoring mechanical solutions over electronical ones

Certain functions traditionally handled by electronics can be effectively replaced by simple and robust mechanical solutions. Switches, levers, springs, or latching systems can often substitute sensors or complex electronic circuits.

This approach reduces the environmental footprint associated with the production and assembly of electronic components while increasing durability. Mechanical components are generally easier to diagnose and replace, and their lifespan often exceeds that of circuits sensitive to overloads or environmental conditions.

Beyond the ecological aspect, mechanical substitution promotes design simplicity and overall product reliability.

Reparability and modularity

Reparability is a central lever of eco-design. Designing a product so that it can be maintained and repaired extends its lifespan and reduces electronic waste.

This involves modular assemblies, accessible screws, standardized connectors, and clear maintenance documentation. Modularity makes it easier to replace faulty components without discarding the entire product. Reparability assessment should begin at the preliminary design stage and be optimized throughout prototyping and iterative development.

Sizing according to real-life needs

An eco-designed product must be precisely calibrated to its actual use cases. Oversizing motors, batteries, or mechanical structures leads to unnecessary waste of materials and energy.

This approach relies on analyzing functional units and real-world usage scenarios to size each component optimally. This not only reduces environmental impact but also lowers costs and avoids unnecessary complexity, while maintaining product performance and reliability.

Eco-design integration process

Eco-design should be approached as an iterative process integrated into product development:

- Ideation phase: Identify user needs, technical constraints, and sustainability priorities. From this stage, consider reparability and mechanical solutions before committing to complex electronic circuits.

- Functional prototyping: Once the first prototype is operational—but before the final form is fixed—this is the ideal time to optimize the design. Reduce components, favor simple mechanical solutions, size according to real usage, and integrate easily repairable modules. At this stage, decisions are based on concrete data obtained from the prototype.

- Final design and industrialization: Once the form is finalized, eco-design choices guide material selection, packaging, assembly, and manufacturing processes. Material reduction, modularity, and component simplicity are integrated to limit environmental impact.

- Testing and iterations: Eco-design remains an evolving process. Field feedback and durability testing help identify continuous improvements, either for the current version or for future iterations.

Why intervene at the functional prototype

The most relevant moment to implement eco-design is after the creation of a functional prototype but before the product’s final form is locked in. At this stage, real needs are identified and usage scenarios are clear, enabling informed decisions about which components to keep, simplify, or replace.

Before this phase, choices are based on assumptions that are often too vague to be reliable. Afterward, modifications can become costly or technically restrictive. Intervening at the optimal moment makes it possible to strike a balance between performance, simplicity, and sustainability.

Conclusion

Eco-design is now a strategic lever for creating high-performance, durable, and responsible products. By reducing electronic circuit complexity, favoring simple mechanical solutions, improving reparability, and sizing each component according to real needs, it is possible to limit environmental impact while optimizing product reliability and value.

At HollowCube, this approach is integrated from the early stages of development, with a particular focus on the functional prototype—an essential moment for maximizing the effectiveness of eco-designed choices. This methodology demonstrates that innovation and sustainability can coexist, and that thinking about the product as a whole is the best way to create long-term positive impact.