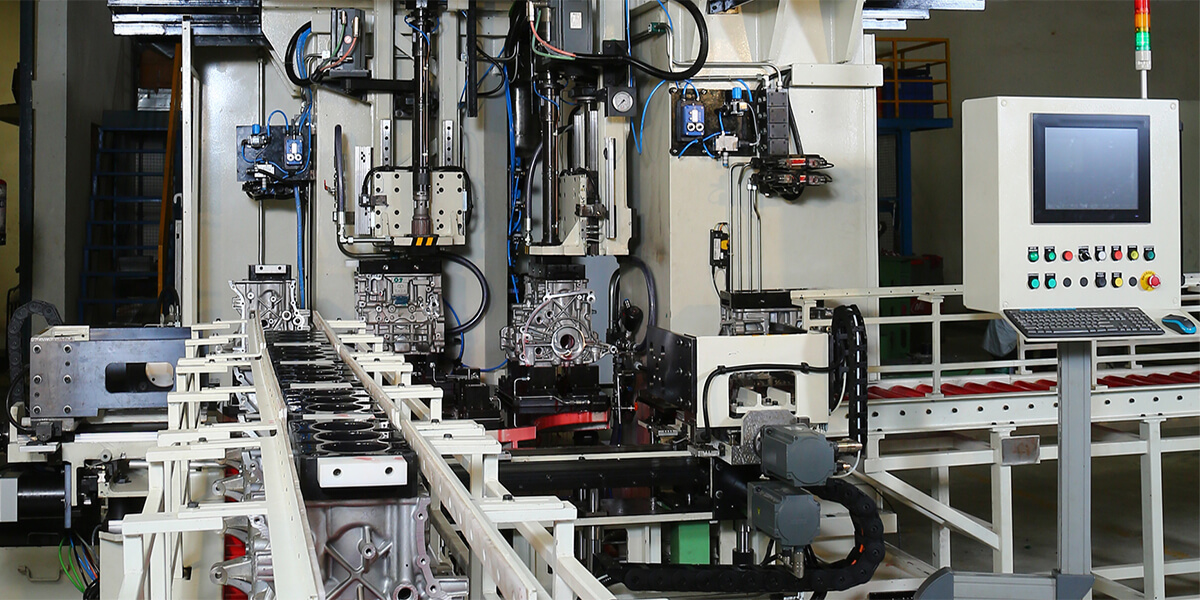

SPECIAL-PURPOSE MACHINES DESIGN AND ASSEMBLY

Our base services

Industrial design, including tolerancing and complex assemblies.

File transmission in native format (SolidWorks) and export.

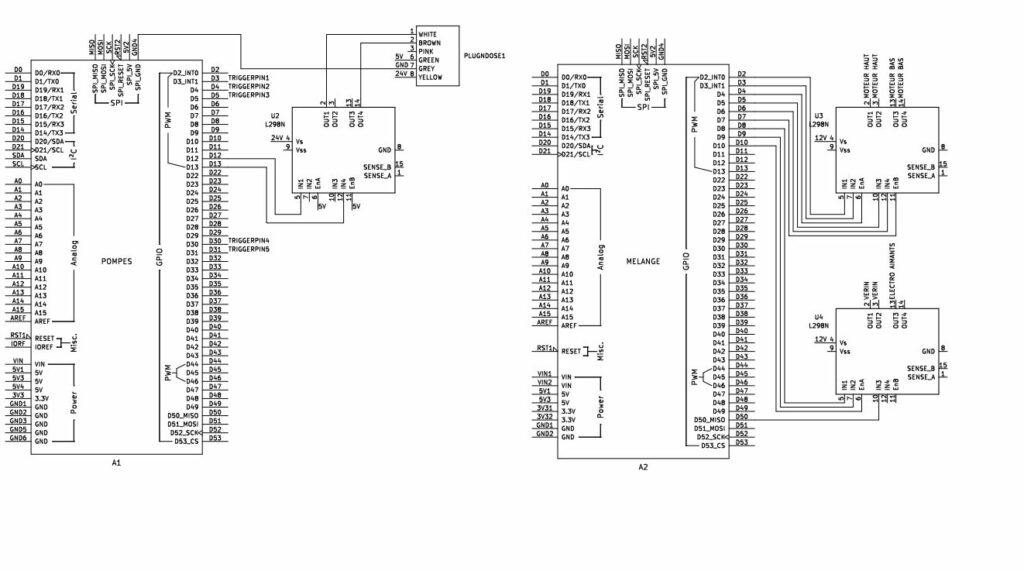

Complete electronic diagrams, definition of actuators and sensors.

Power supply sizing according to needs.

Embedded programming and optimizations, user interface creation and machine integration following your preferences and your current ecosystem.

Our tailor-made process

Specification document

We work together to define your needs and your technical specifications, with the aim of achieving complete and precise initial specification document.

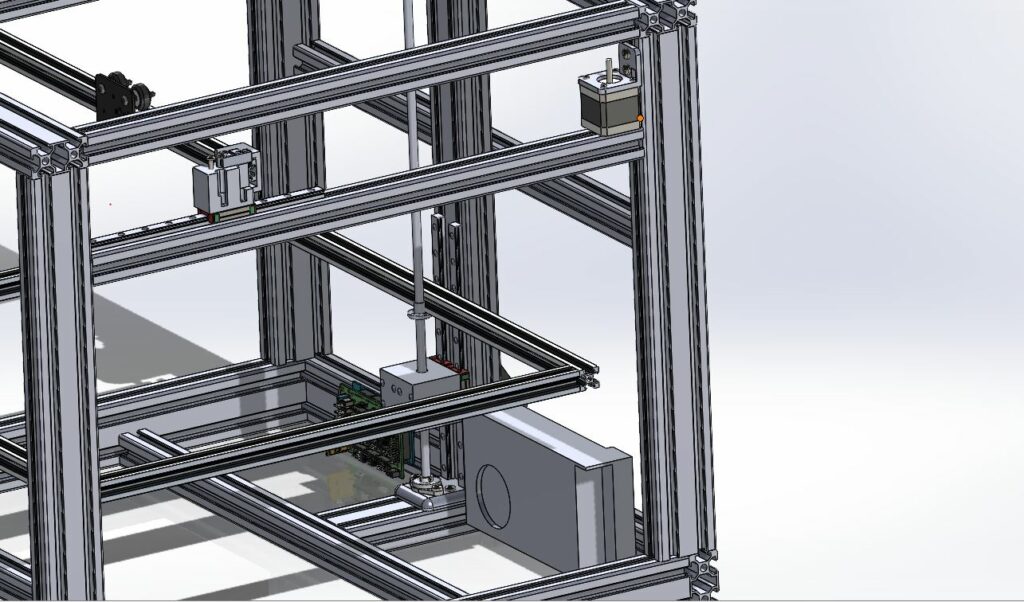

Industrial design

The specification document is used as a basis for CAD. The objective is to meet all the defined constraints while allowing scalability to the special-purpose machine. The definition of actuators/sensors and electronic design are included in this phase.

The BoM (technical nomenclature) and the wiring plan are submitted at the end of this step.

Modeling

If required, the design is tested in simulation under realistic conditions (temperature, force, cyclic, drop constraints). A kinematic study can also be carried out.

Prototype

A working prototype is assembled which will serve as the basis for the final machine. Several iterations can be carried out to implement new features/correct unforeseen circumstances.

Electronic boards programming is included.

Delivery

Once the prototype is validated, a FAT (Factory Acceptance Test) of the machine takes place on our premises. The machine is delivered to you by hand and a SAT (Site Acceptance Test) is carried out at its final location.

Maintenance and continuous improvement of machines can be included in the service, contact us for more information.