PRODUCT INDUSTRIAL DESIGN AND DEVELOPMENT

Our base services

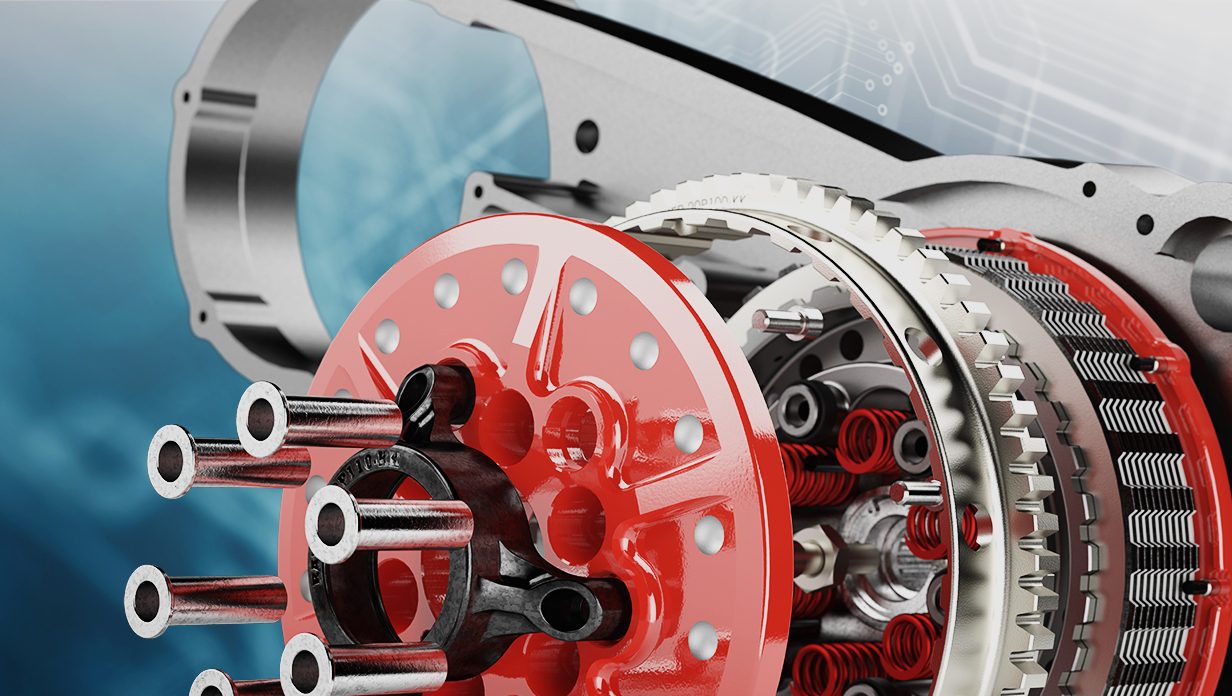

CAD (Computer Aided Design) industrial design, including tolerancing and complex assemblies.

File transmission in native format (SolidWorks) and export.

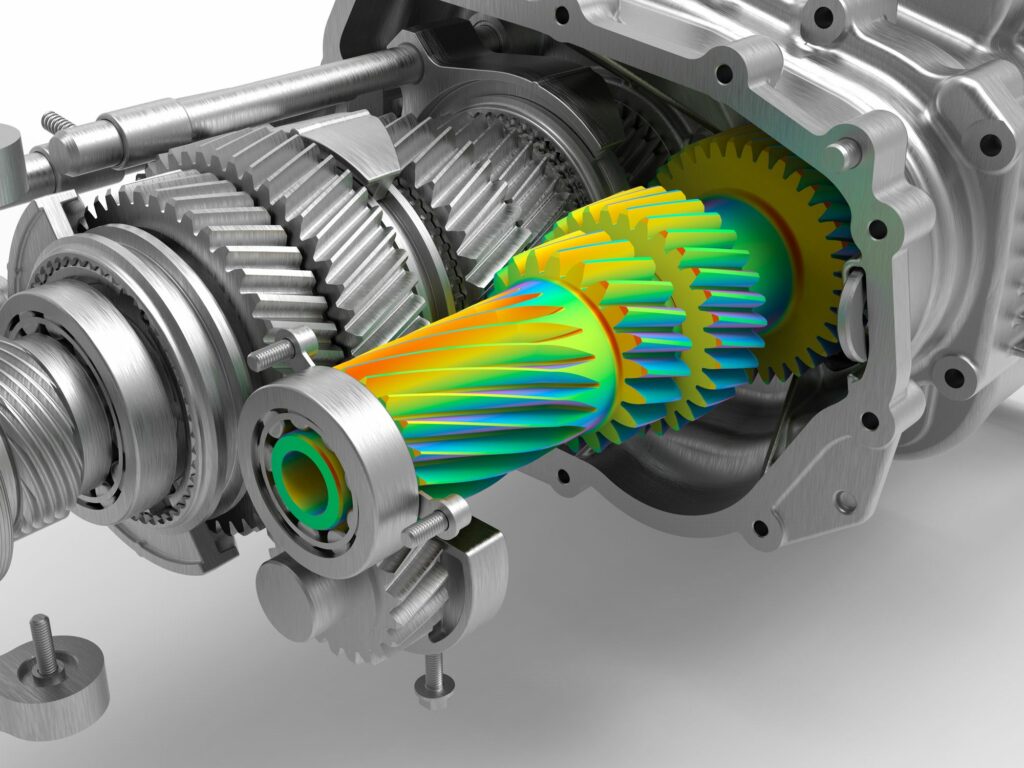

FEA modeling (Finite Elements Analysis) to ensure robustness of the design against real constraints of temperature and force.

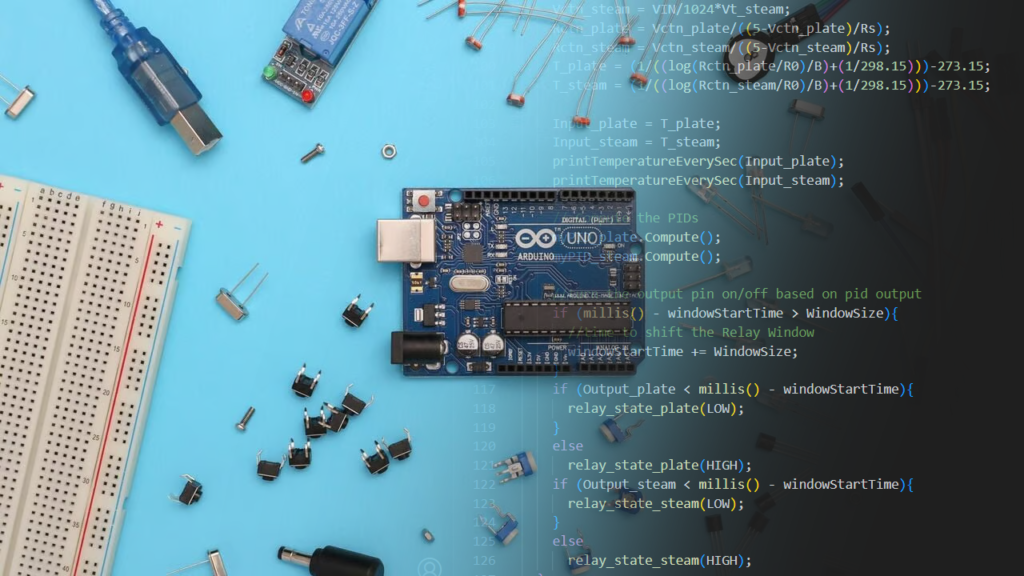

Electronic design, function programming and PCB prototyping. Recommendation in the selection of components and technical support.

Our tailor-made process

Design brief

We work together to define your design needs and your technical specifications, with the aim of achieving complete initial specifications.

Industrial design

The specifications are used as a basis for CAD. Our goal is the optimization of internal volumes and components without affecting the exterior appearance of the design.

The BoM (technical nomenclature) is submitted at the end of this step.

Modeling

If necessary, the design is tested in simulation under realistic conditions (temperature, force, cyclic, drop constraints).

Realistic render

High-fidelity 2D renderings are produced to project the final appearance of your product – and provide input into your slides. 3D video renderings are also possible upon request.

Mock-up

One or more non-functional mockups are manufactured to validate final key factors such as weight distribution and UX.

Prototype

At least one functional prototype is developed using materials and processes as close as possible to the finished product. Several iterations can be carried out to implement new features/correct unforeseen issues.

Prototyping of electronic boards as well as their programming is included.