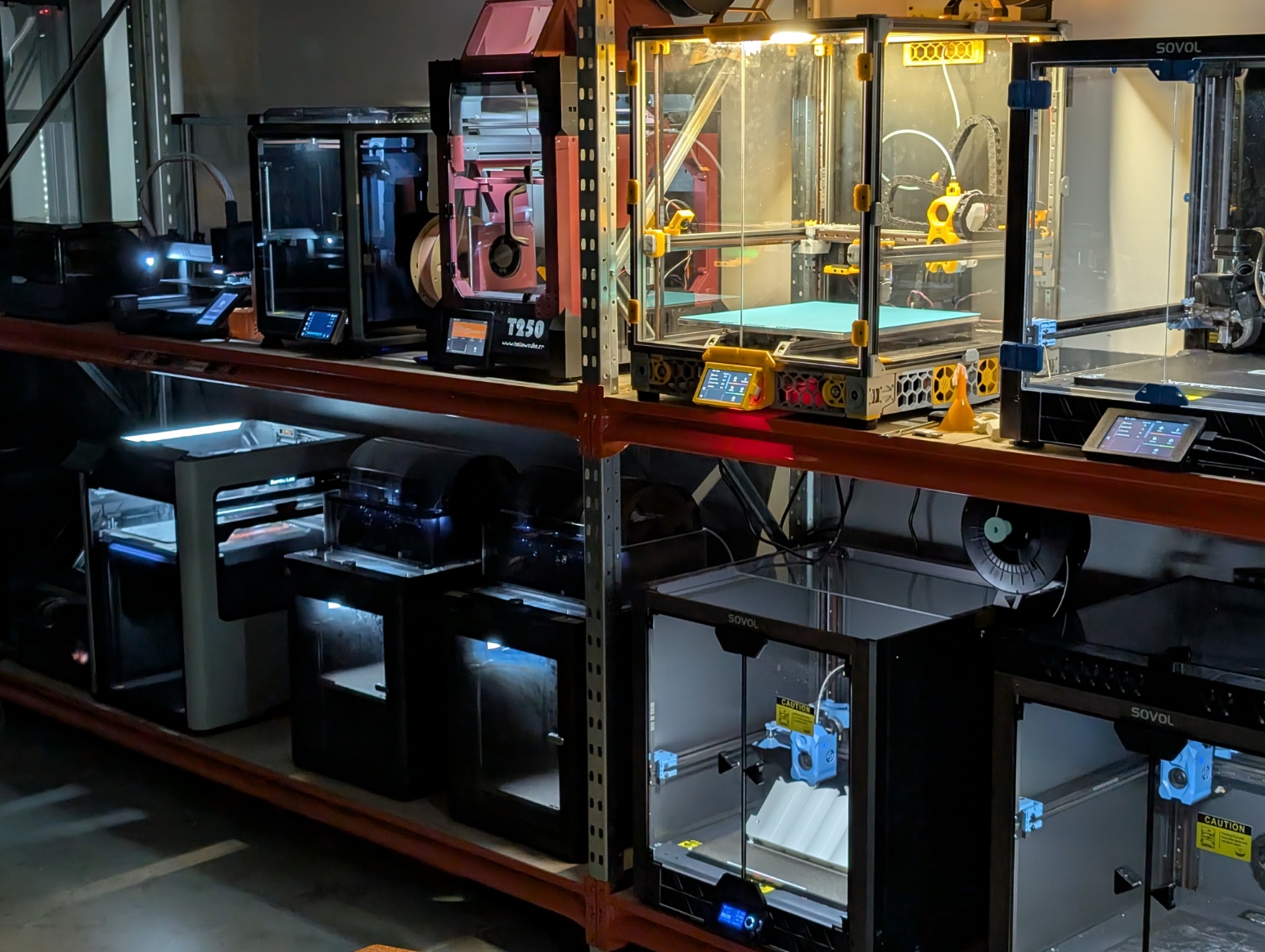

Technologies & machine fleet

Our strength lies in our complete control of integrated prototyping and privileged access to a global network of certified partners. We combine the agility of our in-house workshop, equipped with the latest technologies, with the power of an international industrial ecosystem, thus ensuring quality, speed, and scalability for your most demanding projects.

Our in-house workshop: capabilities & technical expertise

A diverse and high-performing machine fleet dedicated to your innovations. Each technology is selected for its complementarity, enabling an integrated approach from prototyping to pre-production.

Delta FDM

Ø260 x 330 mm

Delta FDM

Ø200 x 200 mm

CoreXY FDM

256 x 256 x256 mm

CoreXY FDM

256 x 256 x256 mm

CoreXY FDM

256 x 256 x256 mm

CoreXY FDM

350 x 350 x 330 mm

Cartesian FDM

250 x 250 x 260 mm

CoreXY FDM

220 x 220 x 250 mm

CoreXY FDM

256 x 256 x 256 mm

CoreXY FDM

270 x 270 x 270 mm

CoreXY FDM

250 x 220 x 270 mm

CoreXY FDM

350 x 350 x 345 mm

CoreXY FDM

192 × 212 × 175 mm

SLA

3D printer

192 x 120 x 245 mm

SLA 3D printer

196 x 122 x 200 mm

SLA 3D printer

218.88 x 122.88 x 220 mm

Thermoforming

200 x 200 mm

Injection molding

3D scanner

CNC machining

360 x 240 x 140 mm

Laser engraving/cutting

400 x 400 mm

Plotter

297 x 3600 mm

Delta FDM

Ø260 x 330 mm

CoreXY FDM

350 x 320 x 325 mm

CoreXY FDM

256 x 256 x256 mm

CoreXY FDM

256 x 256 x256 mm

Delta FDM

Ø200 x 200 mm

CoreXY FDM

350 x 350 x 330 mm

Cartesian FDM

250 x 250 x 260 mm

CoreXY FDM

220 x 220 x 250 mm

CoreXY FDM

256 x 256 x 256 mm

CoreXY FDM

270 x 270 x 270 mm

SLA 3D printer

192 x 120 x 245 mm

Laser engraving/cutting

400 x 400 mm

SLA 3D printer

218.88 x 122.88 x 220 mm

CNC machining

360 x 240 x 140 mm

SLA 3D printer

196 x 122 x 200 mm

CoreXY FDM

350 x 350 x 345 mm

Thermoforming

200 x 200 mm

Injection molding

3D scanner

CoreXY FDM

250 x 220 x 270 mm

Plotter

297 x 3600 mm

CoreXY FDM

192 × 212 × 175 mm

Competitive advantage: Our in-house workshop enables up to 200% faster iteration compared to systematic outsourcing.

Our network of certified industrial partners

Our worldwide network ensures quality, responsiveness, and business continuity, from functional prototype to large-scale production.

Autited and qualified suppliers on three continents

Extensive coverage to optimize costs and lead times

Complete supply chain monitoring and quality control

Accelerate your product development

Leverage our technical resources and industrial expertise to transform your concepts into high-performing products. Our integrated approach reduces lead times, optimizes costs, and ensures a seamless transition to industrialization.

From the first sketch to series manufacturing, we support you at every stage with rigor, transparency and responsivity.

Project audit

Technical analysis and industrial feasibility

Rapid prototyping

Functional validation using our in-house resources

Industrialization

Safe transition to series manufacturing

Non-stop support

Support on quality and process optimization